Vacuum Hardening Vs Nitriding . Each process has its pros and cons. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Nitrided and ferritic nitrocarburized steels offer many advantages: Also, the nitriding process helps in reducing notch sensitivity. The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. They have greater surface hardness relative to carburized steels, exhibit. Plasma nitriding is an established.

from solaratm.com

Nitrided and ferritic nitrocarburized steels offer many advantages: The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Each process has its pros and cons. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. Plasma nitriding is an established. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Also, the nitriding process helps in reducing notch sensitivity. They have greater surface hardness relative to carburized steels, exhibit.

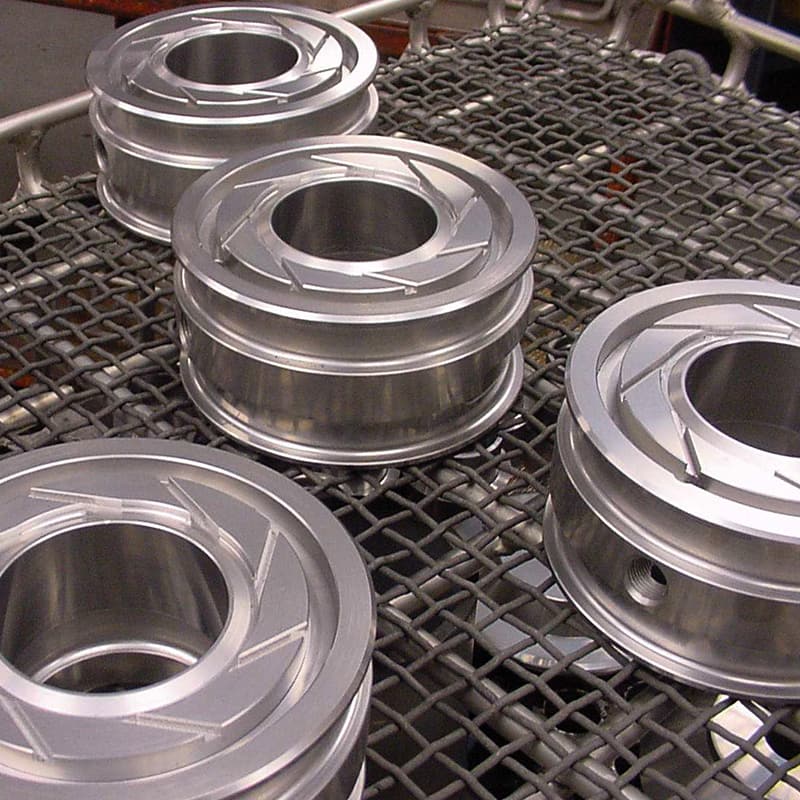

Vacuum Hardening & Tempering Services

Vacuum Hardening Vs Nitriding Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Also, the nitriding process helps in reducing notch sensitivity. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Each process has its pros and cons. Plasma nitriding is an established. They have greater surface hardness relative to carburized steels, exhibit. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. Nitrided and ferritic nitrocarburized steels offer many advantages: Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy.

From www.scribd.com

Vacuum Hardening Hss PDF Heat Treating Steel Vacuum Hardening Vs Nitriding They have greater surface hardness relative to carburized steels, exhibit. Nitrided and ferritic nitrocarburized steels offer many advantages: Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Also, the nitriding process helps in. Vacuum Hardening Vs Nitriding.

From www.slideshare.net

Induction Hardening Vacuum Hardening Vs Nitriding They have greater surface hardness relative to carburized steels, exhibit. The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. Also,. Vacuum Hardening Vs Nitriding.

From www.vacfurnace.com

Ion Nitriding vs Gas Nitriding SIMUWU Vacuum Furnace Vacuum Hardening Vs Nitriding Each process has its pros and cons. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. They have greater surface hardness relative to carburized steels, exhibit. Nitrided and ferritic nitrocarburized steels offer many advantages: Plasma. Vacuum Hardening Vs Nitriding.

From www.youtube.com

Surface hardening process & types// case hardening Carburizing Vacuum Hardening Vs Nitriding Also, the nitriding process helps in reducing notch sensitivity. Nitrided and ferritic nitrocarburized steels offer many advantages: Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Plasma nitriding is an established. They have greater surface hardness relative to carburized steels, exhibit. Plasma nitriding, also known as ionitriding, is a thermochemical process. Vacuum Hardening Vs Nitriding.

From www.youtube.com

Nitriding Case Hardening Thermochemical Treatment Salt Bath Gas Vacuum Hardening Vs Nitriding They have greater surface hardness relative to carburized steels, exhibit. Plasma nitriding is an established. Nitrided and ferritic nitrocarburized steels offer many advantages: Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Vacuum hardening is. Vacuum Hardening Vs Nitriding.

From www.youtube.com

Strain Hardening Strain Hardening Material Technology YouTube Vacuum Hardening Vs Nitriding They have greater surface hardness relative to carburized steels, exhibit. Also, the nitriding process helps in reducing notch sensitivity. Plasma nitriding is an established. Nitrided and ferritic nitrocarburized steels offer many advantages: The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface. Vacuum Hardening Vs Nitriding.

From www.youtube.com

NITRIDING CASE HARDENING PROCESS YouTube Vacuum Hardening Vs Nitriding The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Plasma nitriding is an established. Each process has its pros and cons. They have greater surface hardness relative to carburized steels, exhibit. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Nitrided and ferritic nitrocarburized steels. Vacuum Hardening Vs Nitriding.

From www.longwear-nitriding.co.uk

Overview of the nitride hardening process Vacuum Hardening Vs Nitriding Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Also, the nitriding process helps in reducing notch sensitivity. Plasma nitriding is an established. They have greater surface hardness relative to carburized steels, exhibit. Nitrided and ferritic nitrocarburized steels offer many advantages: The horizontal vacuum furnace and vertical vacuum furnace series deliver. Vacuum Hardening Vs Nitriding.

From www.youtube.com

Nitriding Furnaces and Nitriding Process Nitrex Metal YouTube Vacuum Hardening Vs Nitriding Plasma nitriding is an established. They have greater surface hardness relative to carburized steels, exhibit. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Also, the nitriding process helps in reducing notch sensitivity. Each process has its pros. Vacuum Hardening Vs Nitriding.

From solaratm.com

Vacuum Hardening & Tempering Services Vacuum Hardening Vs Nitriding Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Plasma nitriding is an established. Nitrided and ferritic nitrocarburized steels offer many advantages: Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. They have greater surface hardness relative to carburized steels, exhibit. Each. Vacuum Hardening Vs Nitriding.

From www.slideshare.net

Induction Hardening Vacuum Hardening Vs Nitriding Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Each process has its pros and cons. They have greater surface hardness relative to carburized steels, exhibit. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Plasma nitriding, also known as ionitriding, is. Vacuum Hardening Vs Nitriding.

From www.tec-science.com

Flame hardening of steel (surface hardening) tecscience Vacuum Hardening Vs Nitriding Also, the nitriding process helps in reducing notch sensitivity. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. Plasma nitriding is an established. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Nitrided and ferritic nitrocarburized steels offer many advantages: They have greater surface. Vacuum Hardening Vs Nitriding.

From www.vrogue.co

Hardening Vs Tempering Steel What S The Difference vrogue.co Vacuum Hardening Vs Nitriding Each process has its pros and cons. The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Nitrided and ferritic nitrocarburized steels offer many advantages: Nitriding is a surface hardening process where atomic nitrogen is introduced into. Vacuum Hardening Vs Nitriding.

From www.vacfurnace.com

Ion Nitriding vs Gas Nitriding SIMUWU Vacuum Furnace Vacuum Hardening Vs Nitriding Each process has its pros and cons. Plasma nitriding, also known as ionitriding, is a thermochemical process for the surface hardening of metals. Nitrided and ferritic nitrocarburized steels offer many advantages: The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. They have greater surface hardness relative to carburized steels, exhibit. Also, the nitriding process. Vacuum Hardening Vs Nitriding.

From www.researchgate.net

Surface hardness versus nitriding time at temperatures of 570 and Vacuum Hardening Vs Nitriding They have greater surface hardness relative to carburized steels, exhibit. The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Each process has its pros and cons. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. Plasma nitriding is an established. Also, the nitriding process helps. Vacuum Hardening Vs Nitriding.

From www.researchgate.net

(PDF) Relation between Mechanical Hardening and Nitrogen Profile of Vacuum Hardening Vs Nitriding Also, the nitriding process helps in reducing notch sensitivity. Each process has its pros and cons. Vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative. They have greater surface hardness relative to carburized steels, exhibit. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a. Vacuum Hardening Vs Nitriding.

From www.youtube.com

Heat Treatment part4Surface hardening process & typescase hardening Vacuum Hardening Vs Nitriding The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Each process has its pros and cons. Also, the nitriding process helps in reducing notch sensitivity. They have greater surface hardness relative to carburized steels, exhibit. Vacuum. Vacuum Hardening Vs Nitriding.

From blog.thepipingmart.com

Vacuum Hardening vs Normal Hardening What's the Difference Vacuum Hardening Vs Nitriding Nitrided and ferritic nitrocarburized steels offer many advantages: Also, the nitriding process helps in reducing notch sensitivity. Nitriding is a surface hardening process where atomic nitrogen is introduced into the surface of a ferrous alloy. Plasma nitriding is an established. The horizontal vacuum furnace and vertical vacuum furnace series deliver superior performance for hardening applications. Plasma nitriding, also known as. Vacuum Hardening Vs Nitriding.